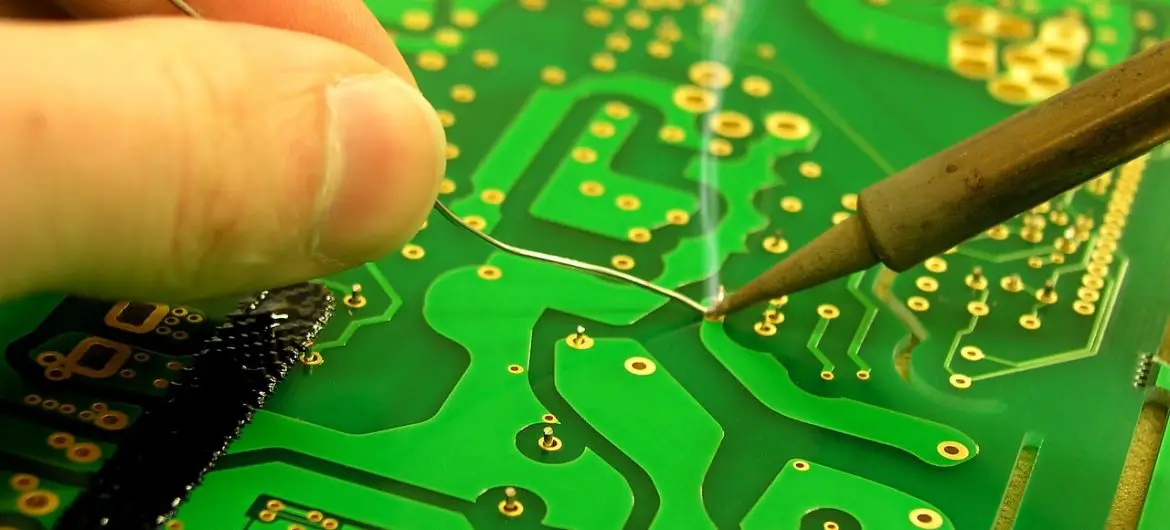

Soldering is a process commonly used in electrical and electronic applications as a means of joining metals together.

The main reason is to create an electrical/mechanical bond between these two metals (or more) to allow electricity to flow.

However, soldering is not limited to just electrical and electronic applications. It can be used for sheet metal, as well as Jewelry and stained glass work.

Solder is the metal alloy material that is used as the ‘glue’ that creates the bond between the two pieces of metal.

But, why do soldering irons get hot? Soldering irons get hot in order to melt the solder which is used to create an electrical and mechanical bond between two pieces of metal. The solder when not heated is a hard substance which will not be able to adhere to the metals being connected together. So, it needs to be heated until it melts with the help of a soldering iron.

Main reason why a soldering irons get hot

I briefly mentioned above why a soldering iron gets hot, but let’s take a deeper look at what is involved with the process of soldering, soldering irons and solder.

Soldering is synonymous with Electrical and Electronic applications.

It can be used to;

- Solder components onto a Printed Circuit Board (PCB)

- Connect two pieces of wire together

- Connect components together

- Fix a broken PCB tracing

These are just some of the many uses of a soldering iron with electrical and electronic applications.

The main objective as we mentioned earlier is to create semi permanent electrical and mechanical bonds since electricity requires a conducting material to move through.

I say semi permanent because it can be reversed using a process known as Desoldering.

Desoldering involves using a soldering iron and either Solder Wick or a Desoldering Gun to remove solder and thereby removing the bond.

This can be helpful if you make a mistake (and many will be made), as well as when components that have failed and need replacing.

What is solder

Solder is a vital component and is the main reason soldering irons get hot.

There are many different types of solder available that come in a variety of metal alloy compositions.

Below are some of the most common solder compositions;

- Tin-Lead (Lead based)

- Tin-Silver-Copper (Lead free)

- Tin-Antimony

- Tin-Copper

- Tin-Silver

However, each of these different compositions of solder does not have the same melting point.

Due to their chemical makeup, and metals used, they vary in temperatures at which they will melt.

Different types of soldering

There are typically three types of soldering processes used; Soft soldering, Hard soldering, and Brazing.

Soft soldering – this type of soldering involves using solder with the lowest melting point and which are typically alloys. Melting temperatures can range from 90°C (194°F) – 450°C (842°F).

Hard soldering – in this process, Brass or Silver are the metals that are used as the solder to create bonds. The melting temperatures involved in hard soldering range from 450°C (842°F) – 600°C (1112°F). Blowtorches are sometimes used to reach these temperatures if a soldering iron is unable to do so.

Brazing – Solder of much higher melting points are used in this process compared to the other two. Temperatures can be higher than 450°C (842°F).

What is a soldering iron

Without a soldering iron, solder would be useless. So, while solder is a vital component, it is one half of the picture.

A soldering iron is the other half that is required that helps unleash the superpowers of solder.

It is an electrical tool which aids in the process of soldering by providing sufficient heat to melt solder in order to join metals together.

Just like solder, soldering irons come in a variety of prices, shapes, sizes, temperature capabilities etc.

Depending on what type of soldering process you are using, as well as what type of solder you will be using, you will need to choose a soldering iron capable of getting hot enough to melt the solder.

But, the better the quality of the soldering iron, the more expensive it is going to be.

So, deciding if you need an expensive soldering iron depends on a couple of factors.

If you need help deciding whether you need an expensive soldering iron or not, click here.

However, you want a soldering capable of a range of temperatures as we now know that different solders have different melting points.

Cheaper soldering irons tend to have one temperature and low wattage which do not get hot enough to melt solder.

Other applications where soldering irons get hot

While its main use is in the electrical and electronic field, a soldering iron is not limited to just them. It has many other applications.

These include;

- Roofing

- Metal Gutters

- Auto Repair

- Jewelry

- Desoldering

- Plumbing

- Stained glass and Mosaics

- Wood burning

With applications like roofing, auto repair, plumbing, jewelry, etc solder is still used so the soldering iron needs to get hot in order to melt the solder.

With wood burning letters are engraved on wood using the soldering iron. Trying to do this with a cold soldering iron is near impossible.

So, again the soldering iron needs to be hot to be able to engrave on wood.

What is the right temperature to set the soldering iron to get hot?

As you saw earlier, there are different types of solder as well as soldering processes which have a range of temperatures at which the solder melts.

So, determining how hot a soldering should be set comes down to the solder you are using.

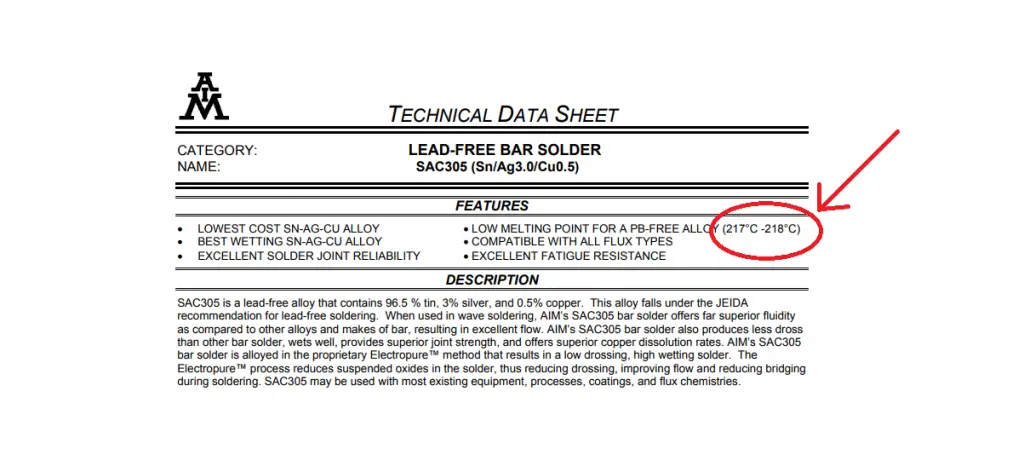

The ranges of temperature at which they melt should be included in the solder’s datasheet which can be obtained from the manufacturer’s website.

Below is a snippet from a solder’s datasheet. As you can see, it specifies the temperature range at which you can set your soldering iron to get hot enough to melt the solder.

If there is no information available, and the solder you are using is a metal alloy, 360 – 400°C is the general temperature to work with.

How hot can a soldering iron get ?

This all depends on the complexity of your soldering iron.

There are typically two types of soldering irons; ones that come as a single soldering iron, and the ones that come as a station with temperature control.

The first type (just the soldering iron) tends to only have one temperature setting (on occasions you can get up to 3 temperature settings).

The temperature output is largely determined by the wattage of the soldering iron.

A soldering iron station will have temperature control which allows you to set a range of temperatures.

Again, the temperature range will vary from brand to brand.

How long does it take for a soldering iron to heat up?

Again, without sounding like a broken record, the time it takes your soldering iron to get hot will depend on the soldering iron itself, as not all soldering irons are the same.

The bigger brand soldering stations will get hot in about 20 – 30 seconds.

Whereas, the soldering irons that are cheaper and have no temperature control can take much longer as they are unregulated.

If you want to be sure of how long it takes, you can always use a timer to see how long it takes from when you turn on your soldering iron to when it starts melting solder.

How do you tell if the soldering iron is hot enough?

The last thing you want to do is burn yourself because you were trying to see if your soldering iron is hot enough.

There are other ways to go about testing whether it is hot or not.

- If you have a digital display it should indicate when it has reached the set temperatures (some soldering irons have an LED indicator)

- Wet sponges are used to clean the soldering iron tip when soldering. Tapping the wet sponge should produce a ‘hissing’ sound indicating it is hot. Also, vapour should be visible.

- Touch solder to the soldering iron to see if it melts. However, if it takes time to melt and only melts a little bit, the soldering is not hot enough. It should melt instantly and turn to ‘liquid’.

What if your soldering iron is not getting hot?

If for some reason your soldering iron is just not getting hot, there are some potential reasons as to why it is not getting hot.

Check this article for more information 6 reasons your soldering iron is not melting solder.