Much like wires carrying current from one part of a circuit to another, or from one component to the next, metallic thread is used to carry current for the same purposes.

Metallic thread, or conductive thread opens the doors to new projects where conventional wire would not be a suitable option.

Some of these applications include sewing on fabrics, embroidery art, creating flexible circuits, wearable art and much more.

But, is metallic thread conductive? Yes, metallic thread is conductive as it is used in electronic circuits where it needs to be able to allow current to flow. Conductive materials like copper, stainless steel allow current to flow whereas insulators inhibit the flow of current. Metallic thread is composed of material like stainless steel which makes it conductive.

How is metallic thread conductive?

To better understand why metallic thread is conductive, let’s take a brief look at conductive materials.

Conductors are certain types of materials that allow the flow of charge (current) in different directions.

The flow of charge happens when an electron of an atom in the conductor transfers its energy to it’s neighbour.

Think of it like when you stack dominos and knock them over.

Insulators on the other hand inhibit (do not allow) the flow of charge.

The main reason for conductors being able to ‘conduct’ electrical current is that the outer electrons of the atoms in conductors are loosely bound and therefore easier to move through that particular material.

Insulators have electrons that are tightly bound to their atoms making it harder to traverse through the material.

What materials are conductive?

Some materials are more conductive than others due to the fact that the outer electrons are held on less tighter to their atoms.

How conductive a material is, therefore allowing it to transfer electrons more effectively is determined by its Electrical Conductivity which is measured in Siemens per meter (S/m).

Therefore, the higher the electrical conductivity of a material, the less resistance is present allowing for a freer flow of charge.

Metals are one of the most conductive materials known, which is why they are used to create wires, components, circuit boards in electrical and electronic applications.

Below is a table of common metals and their electrical conductivity (irom highest to lowest) at 20°C (this is because temperature can affect the electrical conductivity).

| Metal | Electrical Conductivity (S/m) |

| Silver | 6.30 x 107 |

| Copper | 5.96 x 107 |

| Gold | 4.10 x 107 |

| Aluminium | 3.5 x 107 |

| Tungsten | 1.79 x 107 |

| Nickel | 1.43 x 107 |

| Iron | 1.00 x 107 |

| Platinum | 9.43 x 106 |

| Tin | 9.17 x 106 |

What is metallic thread made of?

So, of the many metals available, which ones are most commonly used to make metallic thread conductive?

While there are a range of metallic threads available made using a variety of different conductive metals, the most common metals used are Silver and Stainless steel.

Silver coated metallic threads

The first of the two common metals used to make metallic thread conductive is Silver.

This metallic thread is made by coating a nylon based thread with silver.

Silver coated metallic threads vary in their resistance and therefore need to be used in the right applications.

Using it for large scale projects like a curtain or blanket, will require more thread which will increase the resistance.

Smaller projects like t-shirts would be a better application to use silver coated metallic thread.

Unfortunately, due to having a nylon core, this type of metallic thread cannot be soldered, as the high heat of the soldering iron will melt the solder.

Stainless steel metallic threads

The next metal that is most commonly used to make metallic threads conductive is Stainless Steel.

Unlike silver coated metallic thread, this type does not have a core material that is coated.

This means that it is entirely made up of stainless steel.

As you can imagine, this is going to make it a lot harder to sew as it is not going to be very flexible.

But, compared to silver coated metallic thread, it has a much lower resistance making it ideal for larger projects.

Another advantage of the stainless steel metallic thread is that you can solder it since it does not have a core like nylon which will melt.

Selecting the right conductive metallic thread for your project

So, your next project requires some metallic thread. But, which is the best one for your project?

As we saw above, both the metallic threads have their advantages and disadvantages.

Selecting the right one comes down to the needs of the project as well as your preferences.

Below are some criteria to consider when trying to figure out which metallic thread to choose;

Size of the project

Resistance is the biggest issue here. Since stainless steel metallic thread has lower resistance of the two, it is a better option for bigger projects. As more thread you use, the resistance is going to increase as well.

Whether you need to solder the metallic thread

If you need to solder, silver coated metallic thread is not going to cut it. Again, stainless steel is your best option.

Will there be a lot of sewing involved

If your project requires a lot of sewing, it is going to be very frustrating trying to do so with stainless steel metallic thread, as it is not very flexible. This time silver coated thread is your best option.

Selecting the right metallic thread might not come down to just one criteria, it might come down two or all three.

How can you check if metallic thread is conductive or not?

Maybe you have just bought some metallic thread that does not come with any datasheet, or specifications and are unsure if it is conductive or not.

Is there a way to check whether this thread you have is conductive?

Yes, you can check if a metallic thread is conductive by using a multimeter.

Multimeters have a function known as the ‘Continuity test’ which allows you to test two points in a circuit, piece of wire, metal, etc, to ensure a complete path exists between these two points to allow current to flow.

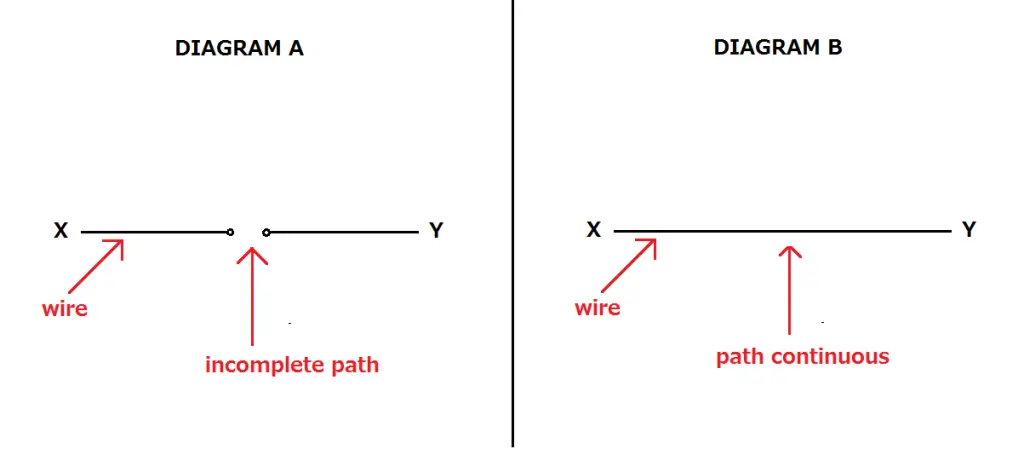

For example, the diagrams below show two pieces of wire.

Diagram A shows a wire that is broken in the middle. If we were to test the wire for continuity between points X and Y, the multimeter would not indicate any continuity as the path is not complete.

However, if we were to test the wire in Diagram B between points X and Y, the multimeter would indicate continuity as a complete path exists.

A note to be made is that the continuity test only works with conductors.

Therefore if you have metallic thread and it is not conductive, the multimeter continuity test will indicate so.

Can conductive metallic thread get really hot?

Since metallic thread is used in applications where it will be sewn into fabric, as well as worn in certain wearable projects, it is a good idea to think how much current will pass through them.

The more current that passes through, the hotter the metallic thread is going to get which will increase the chance of burns or things catching fire.

Ohm’s law is the relationship between voltage, current and resistance which can be seen in the following equation; V = IR.

As the resistance of a material decreases, the current increases (which will cause it to get hotter).

Adding a load like a Light Emitting Diode with a resistor will increase the resistance thereby decreasing the current.

A multimeter will come in handy here again as you can test the resistances of your circuit as well as the amount of current present.