Servo motors are a great way to add controlled motion to a project.

Whether it be moving a robotic arm, tilting the ailerons on a remote controlled plane, used in CNC machines, conveyor belts etc.

Conventional DC motors do not have the ability to rotate to specific positions, however servo motors are designed specifically for just that.

They are designed with a closed loop system that enables it to know which position it is current at for any given time.

To move a servo motor requires Pulse Width Modulation (PWM), which can be generated by a Microcontroller.

But, can you turn a servo motor by hand? You can turn a servo motor by hand, but it is not advisable to do so, especially when it is being powered. Doing so will run the risk of damaging the gears inside of the servo motor. The safest time to move a servo motor by hand is when it is off (no PWM being applied to it). Even then, only do so sparingly.

A look inside the servo motor

Let’s take a quick look inside the servo motor and how it works. (If you already know how it operates or just want to know whether you can turn it by hand or not you can skip this section).

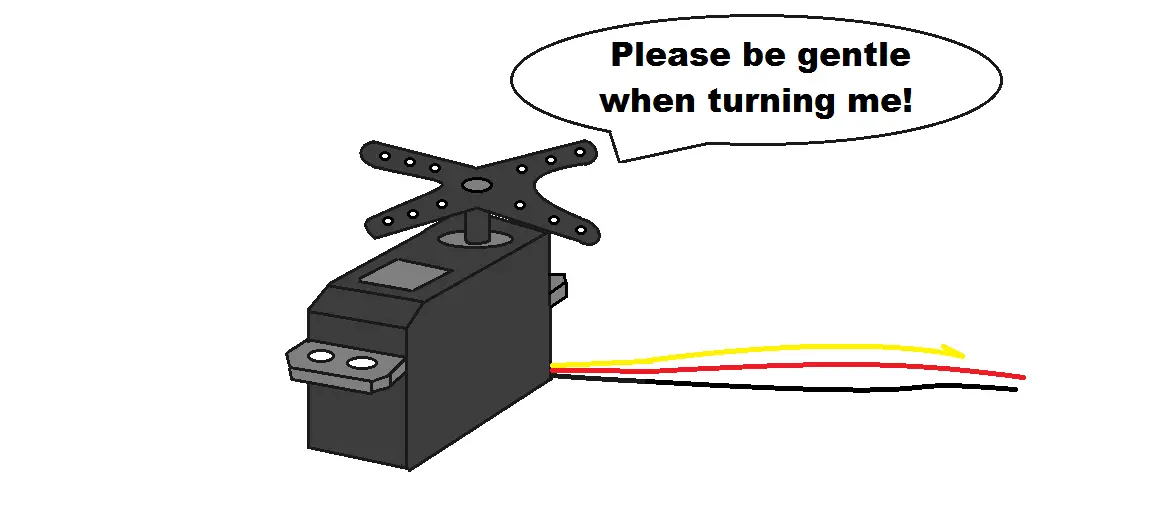

Below is a diagram showing the internals of a servo motor.

From the image above we can see the main parts of the servo motor include the;

- Control circuit

- DC Motor

- Potentiometer

- Gears

- Output shaft

Servo motors are part of a closed loop system incorporating all the parts list above. A closed loop system is needed in order to achieve precise movement to specific positions.

The control circuit is an essential part of the system as it controls all operations.

Think of it as the brain.

A PWM signal is first sent to the control circuit. It then rotates the motor (depending on the Duty Cycle of the pwm signal) which turns the gears thus rotating the output shaft.

The gears are connected to a potentiometer (or a sensor) and as the gears rotate so does the potentiometer thus changing its output resistance which is sent back to the control circuit thus closing the system.

A closer look at the gears of a servo motor

While the control circuit is the central part of a servo motor, for the context of this article and the question at hand “can you turn a servo motor by hand”, the part that we should be concentrating on are The gears.

The main DC motor within the servo motor spins at a high RPM (Revolutions Per Minute) and has a low torque.

This is not helpful for the applications that servo motors are used for.

Therefore, the gears have the job of taking this high RPM of the DC motor and reducing the speed. It also reduces the torque simultaneously.

Cheaper servo motors use gears made of plastic (as plastic is a much cheaper option).

Also, plastic is lighter which helps reduce the overall weight of the servo motor and can be advantageous when using them in an R/C airplane for example.

However, plastic gears are not such a good option where more torque is required for more strenuous work.

For more intense applications, servo motors with metal gears are the better option.

Can you turn a servo motor by hand?

To turn a servo motor we need to supply it with a PWM signal.

But, what if you need to turn a servo motor using your hands? Is it possible?

Yes, it is possible to turn a servo motor with your hands.

However, while it is physically possible to turn a servo motor with your hands, there are concerns as to whether it is a good idea to do so.

Why it is not advisable to turn a servo by hand

The first note to make is that if you need to turn a servo motor using your hand, do so only when it is off (no power is applied to its signal wire).

When a servo motor is being powered there is more resistance as the motor and gears are trying to hold its position.

Trying to turn it now will increase the chances of the gears breaking due to this added resistance.

Another issue that could arise is that as you try to turn it while on, the motor is going to draw larger currents as it needs more power to fight the resistance you are providing while trying to turn it.

This is going to cause the motor to overheat which could damage it.

Also, do not attempt to turn it while it’s in motion (especially in the opposite direction).

This is definitely not a good idea.

As mentioned above, if you really need to turn the servo motor, do it when it is off.

There will be no resistance and current flowing so it will be much easier.

However, constantly turning the servo motor is going to place stress on its gears.

We know that gears can be either plastic or metal.

Plastic gears are used for lower torque applications because they cannot handle the higher stress of higher torques.

If you are turning the servo motor with plastic gears repeatedly and applying forces that it cannot handle, it is going to wear the teeth of the gears or even break them.

Turn plastic gears sparingly and gently.

Other concerns of turning a servo motor by hand

Physically damaging the internal components by turning it by hand is one of the main concerns to consider.

There is one other concern, and that is generating current when manually turning a servo motor.

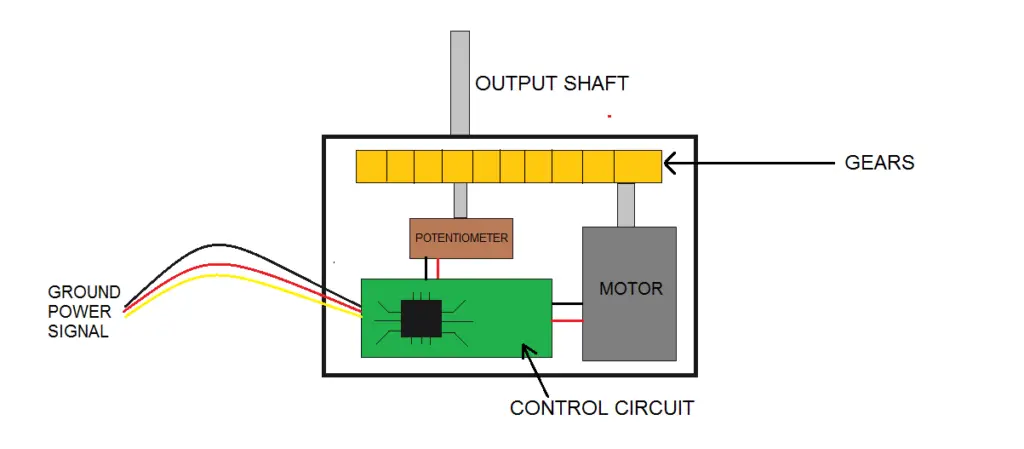

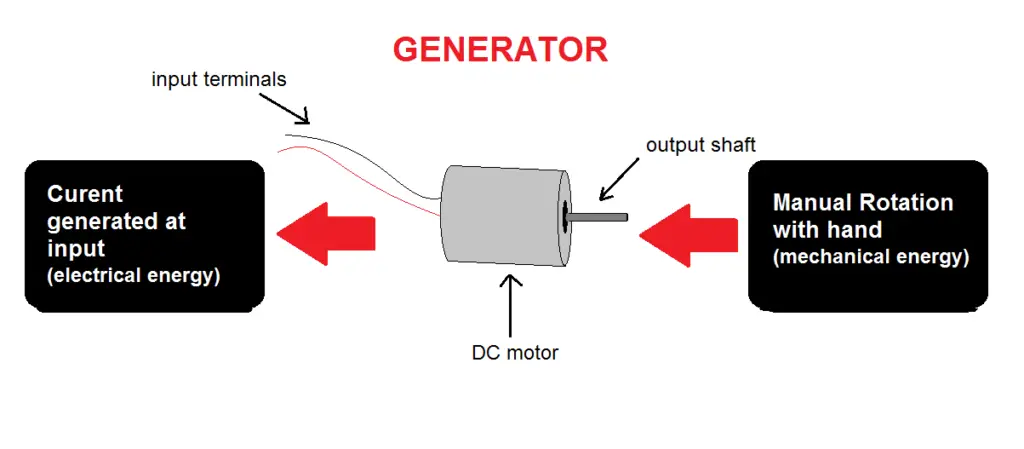

DC motors have the ability to work in either direction; as a motor and as a generator.

When an electric current is applied to its terminals, its shaft rotates. Electrical energy is converted to mechanical energy.

In this configuration it is a motor.

Now if we happen to rotate the motor shaft manually (when no current is applied to it), current is ‘generated’ at the motor’s input terminals. Mechanical energy is converted to electrical energy.

Here it is operating as a generator.

Since the servo motor has a DC motor, we need to be cautious when turning it, as currents could be generated which could damage the internal components of the servo.

But, will the currents be large enough that you should worry about it?

Generating large currents is going to require you to turn the servo quite fast and with a large force.

So, if you need to really turn the servo do so slowly and with less force.

How much force should you use when turning a servo by hand?

As you saw earlier, large amounts of force are not really ideal for servo motors.

Especially ones with plastic gears. This is because the greater the force used to turn a servo with your hand is greatly going to increase the wear and tear on the gears (which could potentially break them as well).

Also, since the servo has a DC motor inside, turning it by hand is going to generate a current. This current is proportional to the amount of force applied.

The greater the force, the greater the current generated and vice versa.

So, how much force should you apply when turning a servo with your hand?

Very little!

Be as gentle as possible and go turn it slowly!