Stepper motors are a unique type of motor that varies in its operation to the conventional DC motor.

Unlike a DC motor which just rotates continuously when current is applied to it, a stepper motor can ‘step’ through different positions precisely at certain angles.

It basically divides up the rotation into a number of steps.

Their rotation can be controlled through the use of a Motor Controller and a Microcontroller.

Due to their controlled rotation, they have a number of specific applications where normal DC motors cannot be used.

Applications such as 3D printers, Printers, CNC milling machines, robotics and much more.

But, can a stepper motor run continuously as well? Stepper motors can run continuously. While they are designed for applications that require precise movement, stepper motors can rotate continuously just like a DC motor. They are not restricted to 360 degrees of movement.

A note to be made is that ‘run continuously’ could also mean whether the stepper motor can be powered continuously for long periods of time. The answer here is yes as well.

I shall cover both scenarios in more detail below.

Deeper look at the stepper motor

Taking a closer look at the stepper motor will give us a better understanding why it can run continuously.

A quick look at the DC motor

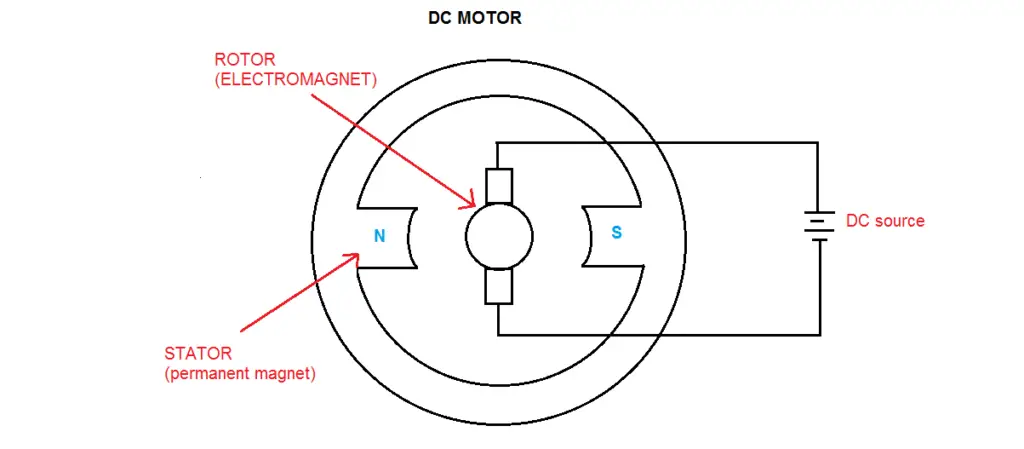

Also, taking a quick look at the DC motor will be beneficial as though they are different, they are similar in their construction.

Above is a diagram of what the internals of a DC motor looks like.

The two main parts of a DC motor are its Stator and Rotor.

The stator is a magnetic housing, and the rotor is a coil of wire. When voltage is applied to the coil of wire, it becomes an Electromagnet.

The forces created due to the magnetic attraction and repulsion between the stator and rotor, cause the rotor to spin.

This is how a DC motor achieves rotation.

However, this rotation cannot be controlled. When voltage is applied, the rotor will spin continuously until voltage is removed with no specific place that it stops.

The stepper motor 00

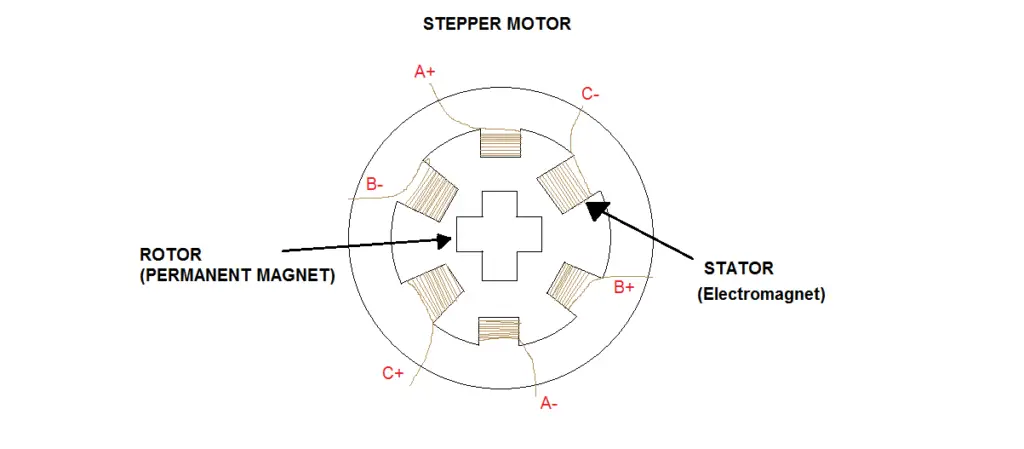

Below is the internal construction of a stepper motor.

It still has a rotor and stator, however they differ in their construction.

As you can see, instead of having permanent magnets, stepper motors use coil windings (electromagnets) as the wire housing (stator).

The rotor on the other hand is a permanent magnet.

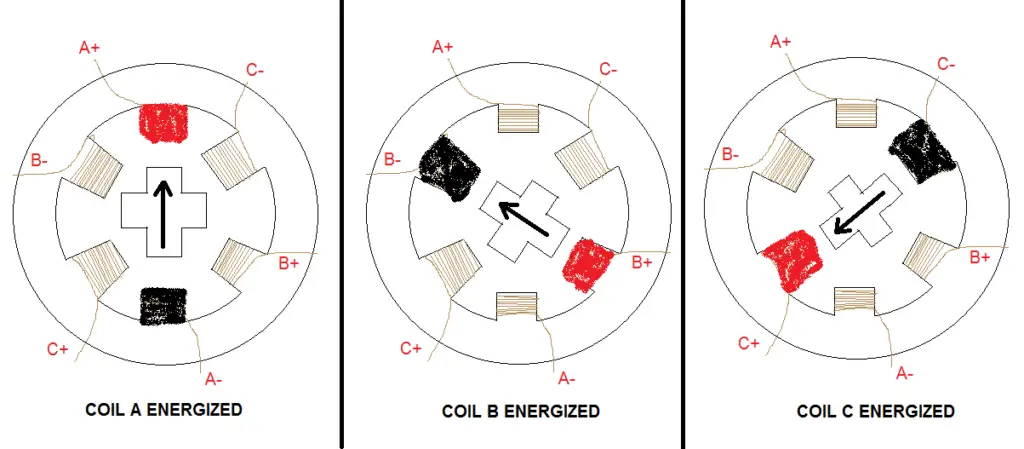

In order to rotate the stepper motor, coils are energized in opposite pairs which causes the rotor to turn a specific number of degrees.

One great advantage is that a stepper motor is part of an open loop system. It does not require sensors to know which position it is at. It just needs to count the number of steps it takes.

Understanding whether a stepper motor can run continuously

Ok, so we took a quick glimpse of the stepper motor and how it works. Now we can answer the question whether a stepper motor can run continuously.

As mentioned at the start of this article, the question could be viewed as meaning either continuous rotation, or powered to run continuously for long periods of time.

Let’s look at both cases.

Stepper motor run continuously: Continuous rotation

The first part of the question we are going to discuss is continuous rotation.

A stepper motor is designed to move in steps through 360 degrees of rotation in either direction.

However, it is not limited to only 360 degrees of movement, it can move continuously just like a traditional DC motor.

The only difference is that it moves in steps.

However, achieving continuous rotation comes down to the motor driver and microcontroller, as making a stepper motor run continuously is not as simple as applying power to its terminals.

It requires switching the power between the different stators in a certain sequence which I will in more detail further below.

Stepper motor run continuously: Powered to run continuously for long periods of time

So, the stepper motor can rotate continuously.

But, can it be powered to run continuously for long periods of time?

Yes, a stepper motor can be powered to run continuously for long periods.

This doesn’t just mean rotation continuously for a certain length of time, but also maintaining a certain position.

What I mean by this is that in order for a stepper motor to hold a certain position, it requires power. Unlike servo motors which can hold a position without the need of power.

One of the many applications of stepper motors is in 3D printers.

The stepper motors in 3D printers sometimes run continuously for hours on end to print really big objects.

Is it a good idea to run a stepper motor continuously?

A follow question to whether it can run continuously is, if it is a good idea do so.

If the stepper motor is rotating, most of the electrical energy is converted to mechanical energy (in the form of rotation).

However, when held at a certain position, stepper motors can waste a lot of that power as most of this energy is lost in the form of heat in the stator coils.

So, if you have to hold a stepper motor in a certain position, do so only for a limited amount of time.

How to make a stepper motor run continuously

To run a stepper motor continuously requires more than just applying a voltage to its terminals.

It requires energizing and degenerzing coils within the motor in a certain sequence in order to achieve rotation.

Below are the steps on how to make the stepper motor rotate continuously as per the diagram above;

- First, Coil A is energized and the rotor is aligned with the magnetic field Coil A produces

- Then Coil B is energized and Coil A is de-energized

- This then causes the rotor to step through a certain angle and align with the magnetic field Coil B produces

- Finally, Coil C is energized and Coil B is de-energized which causes the rotor to rotate a certain angle and align with Coil C’s magnetic field.

To make the stepper motor rotate continuously, just keep repeating steps from 1 to 4 indefinitely.

Doing this requires a motor driver along with a microcontroller which has the ability to energize and de-energize the coils as required.

When would a stepper motor be used to run continuously?

Even though a stepper motor is designed for precise movements, it can still be used in applications that require it to run continuously whether it be continuous rotation or running continuously for long periods of time.

The added benefit you get of using a stepper motor to run continuously is that you will know how many times it has rotated by counting the number of steps it has taken.

This is great for applications such as 3D printers, and CNC milling machines where precise movement and continuous rotation are both needed.