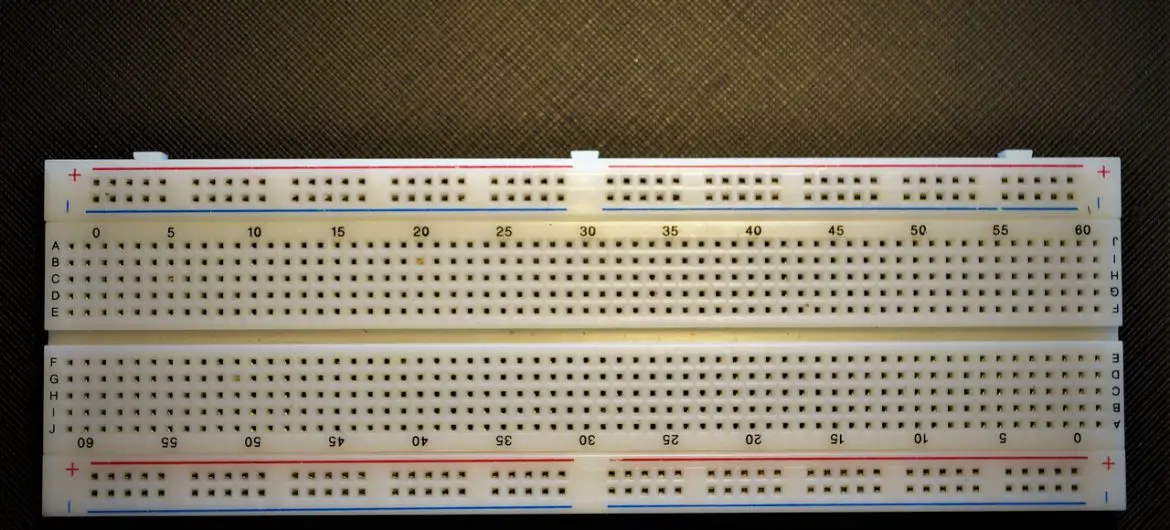

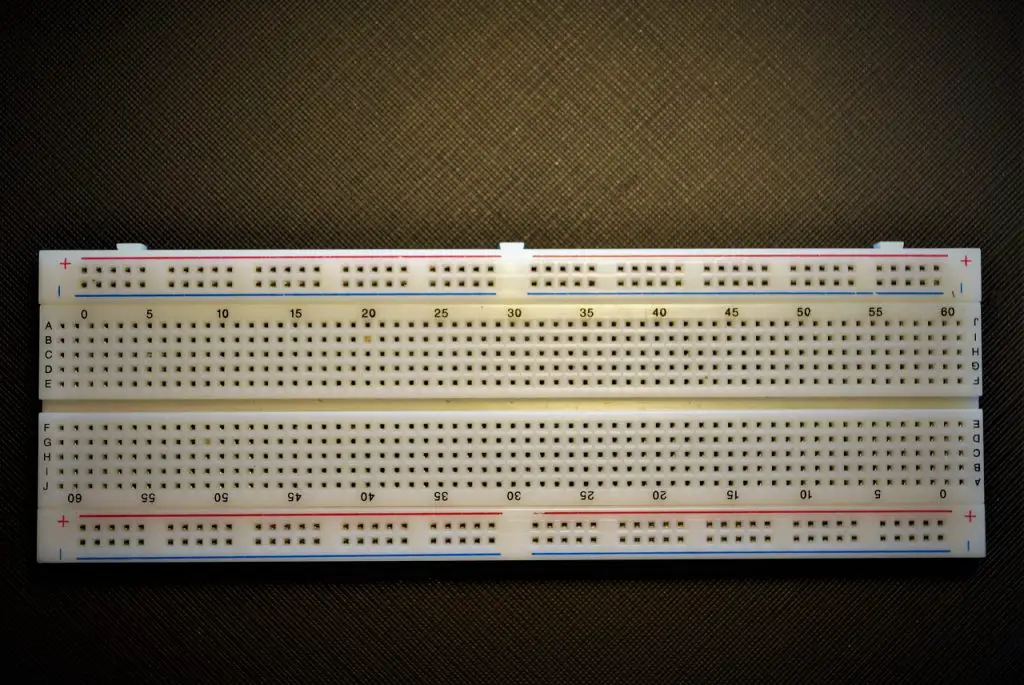

The breadboard is a great tool that can be found on every electronic workbench.

It is used for prototyping and testing temporary circuits. If you have an idea and want to test it out without having to solder any components, the breadboard is your best option.

Things never go as planned, so having the ability to change things on the fly are one of the biggest benefits of using this versatile tool.

It comes in a range of ratings,shapes, and sizes to suit your needs.

Can a breadboard handle 12v? Breadboards are mostly used for low voltage and current applications, however, breadboards can handle 12 volts. Breadboards are made by different manufacturers, so the voltages they can handle depends on how they are constructed. The voltage and currents that a breadboard can handle are displayed on the breadboard datasheet.

The ratings of voltage of the breadboard found on its datasheet are the maximum values that the breadboard can handle. However, it’s not good practice to operate at those voltages all the time.

Common voltages breadboards can handle

As mentioned earlier, breadboards do not all have the same specifications when it comes to what voltages they can handle.

The voltages will vary from one breadboard to the next, depending on the manufacturers.

However, after doing some research, I have found that the average maximum voltage that a breadboard can handle is 36 volts, and the maximum current that it can handle is 2 amps.

So, you will not have any problems running a voltage of 12 volts on your breadboard.

Caution should be taken when running high voltages and currents through a breadboard. If it starts to overheat, that is an indication that the breadboard cannot handle that voltage and current level.

While breadboards have maximum and minimum ratings, it is not advisable to operate at these levels.

Cheaper breadboards might not be able handle 12v

The breadboards that I have researched which can handle 12v and above, were the go to choice when it came to prototyping.

But, these did tend to be on the more expensive side.

You might opt to go for cheaper breadboards as you might be strapped for cash. If you do choose to go with a cheaper breadboard, make sure to check the datasheet for its voltage ratings. If it does not have the value of voltage it can handle, it is best to stay away from it.

If you do choose to purchase it, do your best to test the maximum voltage it can handle first before testing any of your circuits on it.

Your best option is pay a bit more money and get a breadboard that has already been tested for the maximum voltage it can handle. It will benefit you in the long run!

Is voltage the only rating to consider what a breadboard can handle?

There is more to the question of whether a breadboard can handle 12 volts or not. The thing to consider is how much current is flowing through the breadboard at that voltage.

As I mentioned earlier, most of the breadboards sold on popular electronic websites can handle currents up to 2A.

So, if you were prototyping a circuit on your breadboard at 12 volts and running a current of say 500 mA, your breadboard will be able to handle it with no problem at all.

However, if you are running currents of 2A and above while operating at 12 volts, you are going to run into some problems.

Even though your breadboard can handle up to 2A, its best practice to stay well below that value. This will prolong the longevity of your breadboard.

What factors determine how much voltage a breadboard can handle

The factors that determine how much voltage a breadboard can handle, all come down to the construction of the breadboard, and what materials are used.

In electronics and electrical circuits we know wires carry current. The wires are made of conducting materials that allow this current to flow freely.

Copper is a common conductor used in the construction of electrical wires.

The cross sectional area of wire determines how much current it can handle. The larger the cross sectional area, the larger the current and vice versa.

If a smaller wire is used with a larger current, the wire will overheat and melt the insulation which could lead to a short circuit.

Breadboards are a combination of plastic and metal. The breadboard consists of Terminal strips, Power Rails, Outer Shell, and Holes (for component leads).

The terminal strips sit beneath the outer shell (which is made of plastic) to provide a barrier between the components and the terminal strips.

The terminal strips are made of a conducting material which can either be aluminium or copper. How much voltage and current it can handle is also determined by its cross sectional area.

If the terminal strips cross sectional area is small, then it will not be able to handle high voltages or currents.

Does the dimensions of breadboard matter if it can handle 12v?

Of the boards that I researched, both large and small dimension breadboards had the capacity to handle 12v.

So, the dimension of the board did not matter when it came to handling a voltage of 12v.

However, the dimensions could have an influence on whether a breadboard could handle higher voltages, say 24 volts or higher.

This is probably due to the fact that as the dimension of the breadboard increases, the terminal strip cross sectional area can increase, allowing it to carry higher voltages and currents.

Where to find the voltage ratings a breadboard can handle

The best place you can find out how much voltage your breadboard can handle is on its datasheet. The datasheet is a document that is produced by the manufacturer of the breadboard.

It includes information of the materials used to construct the breadboard, dimensions, maximum voltage ratings, maximum current ratings, how many holes it has for components and much more.

When purchasing a breadboard, the website you are purchasing the breadboard from will have its datasheet on the product page. If not, you can visit the manufacturers website and find the datasheet there.

What can you do if you can’t find out how much voltage your breadboard can handle

Sometimes unfortunately, some datasheets do not include the voltage and current ratings for the breadboard you have purchased.

So, how can you know what the maximum voltage and current ratings are?

You will have to test this for yourself.

Do this however, without any circuitry present on the breadboard.

To do this, apply a voltage to the breadboard.

Start a 5 volts and increase the current incrementally every time checking to make sure the breadboard is not overheating.

When it does start to overheat, make a note of the current. Repeat this for higher voltages (12, 24,36 etc).

After this you will get a fair idea of what kind of voltages and currents your breadboard can handle.

Why it’s good practice to check how much voltage a breadboard can handle

Knowing how much voltage and current your breadboard can handle is the best possible information you can know before even prototyping any of your circuits.

If you jump into testing your circuit at voltages and currents much higher than the breadboard can handle you run the risk of frying your breadboard.

A high current through your breadboard will cause the terminal strips to heat up and eventually fail. This can cause short circuiting which will set you back considerably.

It might even melt the plastic shell of the breadboard!

So, remember to always double check how much voltage and current your breadboard can handle before you start testing any of your circuits.

Can a breadboard handle 24 volts?

This depends on the ratings of the breadboard, but of the breadboards I have researched they can handle 24 volts.

But, it also largely depends on the amount of current that is used.

If your circuit is only consuming low currents (below 1A) it should be much of a problem. Problems start to arise when higher currents are used at this voltage.

What are other alternatives to a breadboard that can handle higher higher voltages

If you really need to test circuits at higher voltages and currents, you have other options than a breadboard which will be able to handle the increase in voltage and current.

A Protoboard is another way you can test circuits before you have to design a printed circuit board. Other names for a Protoboard are Perfboard and Stripboard.

They are made from a sheet of resin with a grid of holes, covered in copper. The only downside of using a Protoboard is that you will need to solder components. But, you will be able to use higher voltages and currents.

Breadboard basics

If you are new to electronics or prototyping circuits using a breadboard, check out the video below.

Happy testing!